JAIVIC Capacitors are designed and manufactured with the latest technology by ‘Jaivic Electromech Engg. Pvt. Ltd.’ At their most modern plant at Nasik. The Organisation is backed by a team of people having years of experience & expertise in the field. Hundred percent capacitors are thoroughly tested at every stage of manufacturing and all the routine and type tests are rigorously carried out as per IS: 13925 with latest version. This ensures excellent trouble-free service under most critical conditions of operation.

`JAIVIC’ H.T. Capacitors are used in various applications such as, in distribution systems in mines, Electricity boards, in Industries, for testing application etc. These are used across big motors for lift irrigation schemes, water supply etc. For Power Factor Improvement.

Each Basic element is wound in clean & dust free atmosphere on fully automatic HT Winding machine with the help of Electrical grade Imported biaxially oriented polypropylene film and a high purity soft annealed Aluminum foil.

The Winding of element is flat type. The Elements connected in parallel are formed in series groups to meet the voltage requirement.

The complete stack assembly is insulated with high grade electrical insulating material to get the desired insulation level. And total stack inserted in CRCA/SS container. For terminals of capacitor using high class glazed porcelain bushings.

The capacitor are dried under high vacuum and impregnated by synthetic liquid (PXE) under accurately controlled conditions.

Capacitors are designed to have very low loss generally less than 0.2 watts per kvar.

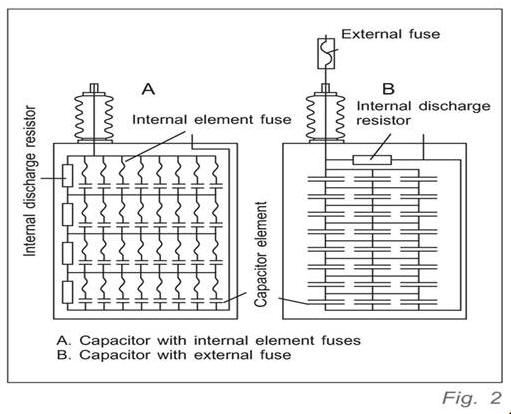

Every individual capacitor element is protected by fuse. In case of element failure during abnormal condition, only one element is disconnected, after disconnection of faulty element, the capacitor unit restores the normal operation within milliseconds with a slightly reduced output. Due to internal fuse the risk of case bursting is considerably reduced.

Standard Capacitors are Available: in 1.1, 3.3, 6.6, & 11 kV voltage class and in Output rating of 50Kvar to 500 Kvar in single unit, Different ratings are available on request.

Routine Electrical tests are carried out as per IS: 13925:1998, Type test are carried out as per customers requirements.

0.2% reactor can be used to limit switching surge current parallel operation of Capacitor banks, Reactors are manufactured as per ISS 5553 Part II.

Detailed dimensional drawing available on request.

If you need any further technical information, Please write to us and we would be willing to provide the same.